Bell & Evans

Stats.

413,370 SF slab-on-grade

58,705 SF trap rock at freezer

45,035 SF mud slab

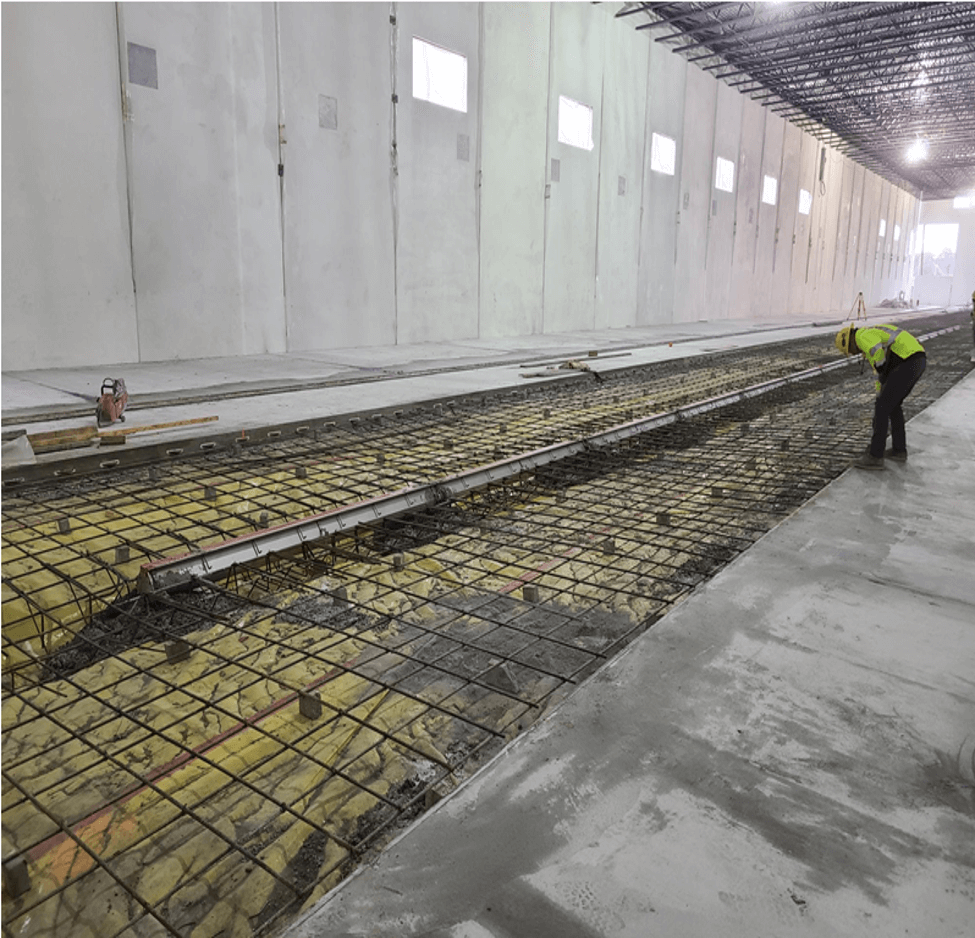

370 Tons rebar

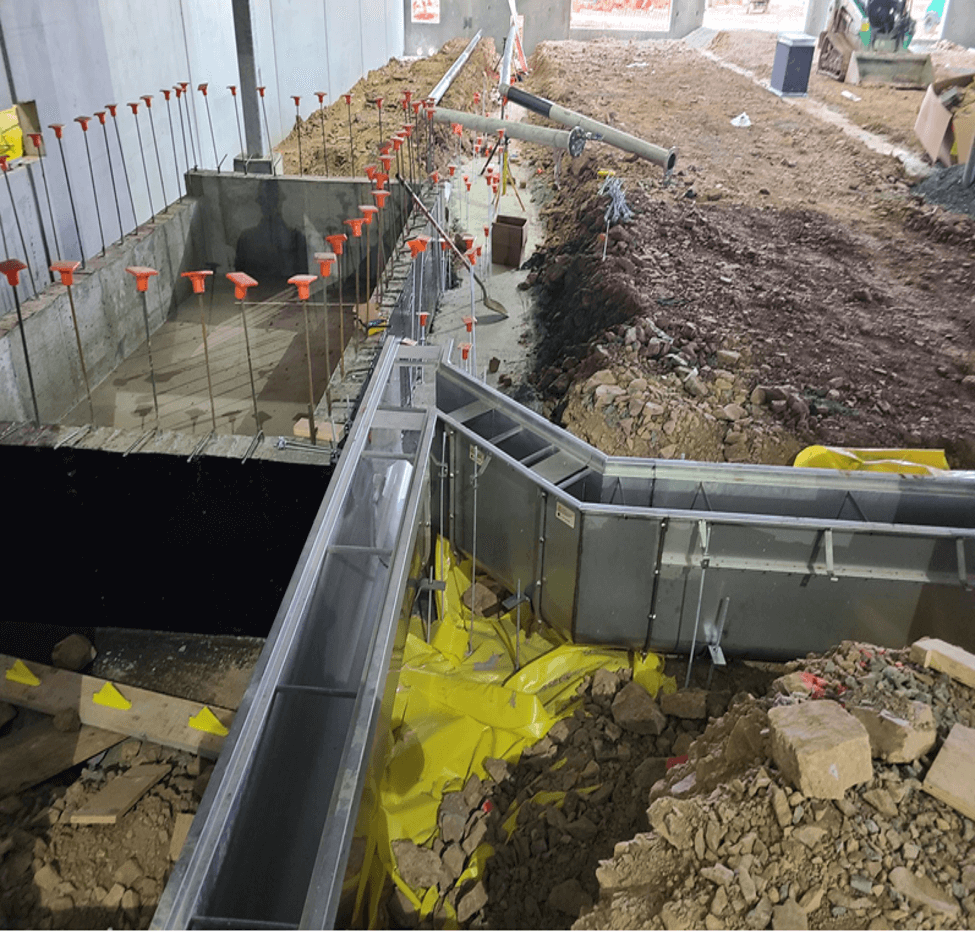

8,236 LF trench drains

1,949 LF curbs

51 Total slab pours rebar reinforced

Synopsis

The Bell & Evans project was a very intricate job featuring a large area of sloped slab for drains, refrigeration rooms, and mechanical rooms with a great deal of reinforcement to meet the specs of a USDA-grade food processing plant. T&T Construction Management Group was faced with unique construction methods such as hand screeding, concrete slab pumping following precast installation, trap rock placement, and rebar tying for the whole slab.

Our team dedicated an ample amount of time planning on this job, and we followed the input of many experts both inside and outside T&T Construction Management Group to make this a success. Despite the many obstacles we faced, our team completed this project in time for the plant’s opening at the end of 2021.

Project Challenges

-

The trap rock operation was a challenge due to the coordination of screed, track rock topping spreader, rebar mat installation, and dowel basket installation. Much planning took place internally to make this operation a success. This also required a great deal of communication with Boger, the concrete supplier, and SSI to get our mix design dialed in for optimal bleed water. The team performed 3 total test slabs. Many spreader machine adjustments were necessary to ensure proper trap rock coverage. This diligent process resulted in high-quality slabs.

-

The extensive sloped slab that was required for the facility floor required immense planning and coordination with the dairy tile flooring installer and coordination with ready-mix supplier in getting consistent slumps. In total we installed over 2,000 linear feet of sloped slab with integrated industrial trench drain.

-

A large amount of slab was poured in the winter during brutally cold temperatures and snowy conditions. This required even more pour planning, concrete truck access prep, ground heater installation, blanket work, and safety measures for the field team. Our team was able to successfully make these pours with concrete and conditions while following ACI (standards and industry best practices throughout construction,) the whole time.